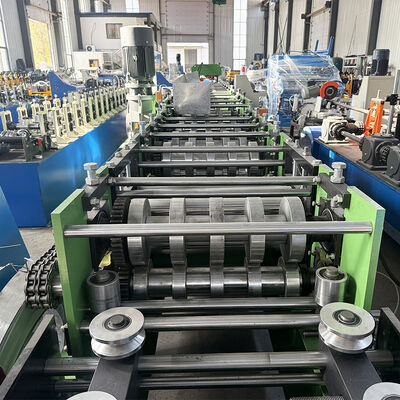

Arrêt automatique coupant la botte de toiture de Purlin de C faisant le petit pain formant la machine

Cette machine de formage de rouleaux d'acier CZ entièrement automatique permet une conversion rapide entre les profils en acier C et Z, permettant des changements rapides de spécifications de 80 à 300 mm en une minute. Le système avancé de coupe de formage permet une coupe continue sur toute la gamme sans changement d'outil. Les caractéristiques incluent un réglage automatique du centrage au niveau du port d'alimentation, une coupe précise à longueur fixe et des vitesses de production élevées de 8 à 15 m/min, réduisant considérablement les coûts de main-d'œuvre tout en améliorant l'efficacité de la production.

Spécifications techniques

| Paramètre |

Spécification |

| Largeur du matériau d'alimentation |

Selon profil |

| Épaisseur du matériau d'alimentation |

Maximum 3,0 mm |

| Largeur des pannes |

100-300mm |

| Hauteur des pannes |

40-80mm |

| Stations à rouleaux |

14 postes |

| Matériau du rouleau |

Gcr15, dureté du traitement de trempe 55-58 |

| Vitesse de formage |

10-15 m/min |

| Moteur principal |

15 kW |

| Méthode de conduite |

Transmission par chaîne |

| Énergie hydraulique |

5,5 kW |

| Système de poinçonnage |

Pré-poinçonnage hydraulique |

| Matériau du moule de poinçonnage |

Cr12 |

| Système de coupe |

Prédécoupe hydraulique |

| Matériau de la lame |

Cr12 |

| Tolérance |

±1,5 mm |

| Tension |

380V 50Hz 3 phases |

| Poids de la machine |

13 tonnes |

| Longueur de la machine |

10m |

| Système de contrôle |

Automate Panasonic |

| Capacité du dérouleur |

5 tonnes |

Principales fonctionnalités

Structure robuste

Conçu avec un comportement mécanique supérieur pour une durabilité et des performances maximales dans des conditions industrielles intensives.

Rouleaux de précision

Les rouleaux sont soumis à deux processus d'usinage et de trempe CNC, atteignant une dureté de HRC 58-62 pour une durée de vie prolongée.

Réglage automatique de la largeur

Capacité de changement de largeur flexible de 80 à 300 mm en standard, avec une capacité maximale jusqu'à 120 × 350 mm.

Système de coupe universel

Tailles de coupe flexibles avec les matériaux de coupe Cr12 et MOV. Intervalle d'entretien : réaffûtage requis tous les 20 000 à 30 000 cycles de coupe.

Composants de contrôle haut de gamme

- Contrôleur API - Siemens

- Transducteur - Yaskawa

- Encodeur - KOYO

- Autres composants électroniques - Schneider

Avantages des machines

- Modifications rapides des spécifications des pannes en 5 à 10 minutes

- Le système de découpe et de poinçonnage rapide C/Z de quatrième génération élimine le besoin de changer de moule de découpe

- Supérieur aux systèmes traditionnels qui nécessitent des changements de moule fréquents, ce qui permet d'économiser du temps et de l'espace de stockage

Emballage et paiement

Les composants importants sont protégés avec de l'huile antirouille, les rouleaux et les arbres sont enveloppés de mousse et les stations hydrauliques, les boîtiers de commande PLC, les pièces de rechange et les petits composants sont emballés dans des boîtes en contreplaqué. Tous les composants sont solidement fixés avec du fil d'acier pour l'expédition par conteneur.

Conditions de paiement :30 % T/T après la signature du contrat, solde dû avant la livraison.

Garantie et assistance

Garantie:18 mois avec support technique à vie

Entraînement:Un technicien pour une semaine (comprend l'installation et le réglage)

Coûts de formation :L'acheteur couvre le visa, le billet aller-retour, la nourriture, l'hébergement et un salaire de 100 USD/personne/jour.

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!