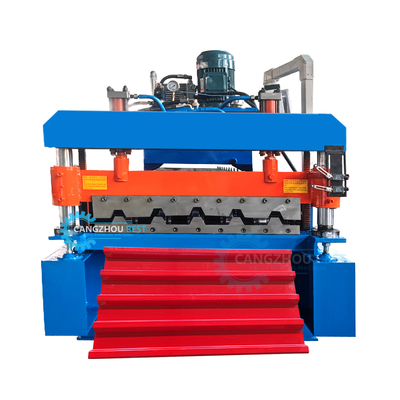

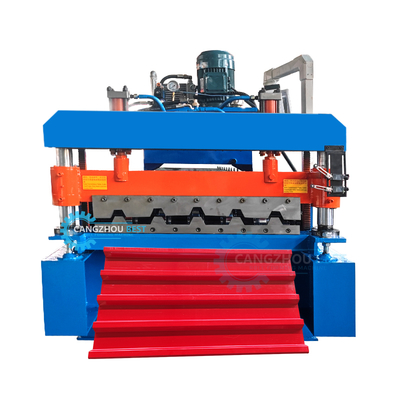

Machine de formage de rouleaux de tuiles de toit à double couche - Machine à double couche de plaque de toit en trapèze

Spécifications du produit

| Attribut |

Valeur |

| Nom |

Machine de formage à rouleaux de tuiles de toiture à double couche |

| Matériau du rouleau |

45# acier poli et recouvert de chrome |

| Matériau de l'arbre |

45# acier poli et recouvert de chrome |

| Diamètre de l'arbre |

70 mm |

| Épaisseur du panneau de cadre |

20 mm |

| Cadre inférieur |

Acier à section H |

| Puissance du moteur |

3 kW |

| Matière première |

0.3-0,8 mm |

Description du produit

Différentes machines de formage de panneaux de toiture peuvent produire différentes formes de tôles de toiture en acier selon les dessins et les exigences du client.Le toit en acier et les parois sont de nouveaux matériaux de construction de différentes épaisseurs et couleursLes produits finis sont utilisés comme toit et murs de gymnases, aéroports, théâtres, usines, entrepôts, garages et centres d'exposition.

Flux de travail:

Décoiler → Alimentation → Formation de rouleaux → Coupe sur longueur → Tableau de sortie

Principaux paramètres techniques

1. Décoiler

- Largeur maximale: 1250 mm

- Diamètre intérieur: Φ450 à Φ550 mm

- Diamètre extérieur: 1500 mm

- Capacité de chargement maximale: 5000 kgs

2. machine à former des rouleaux

- Épaisseur du matériau: 0,2-0,8 mm PPGI et GI

- Nombre de stations à rouleaux: 16 groupes

- Matériau pour rouleaux: acier de haute qualité 45# poli et recouvert de chrome HRC5560°

- Matériau pour l'arbre: acier de haute qualité 45# poli et recouvert de chrome HRC5560°

- Diamètre de l'arbre: 70 mm

- Épaisseur du panneau de cadre: 20 mm

- Cadre inférieur: acier à section H 350

- Puissance du moteur: 3 kW

- Type d'entraînement: 1 "chaîne

- Vitesse: 8 à 12 m/min

3. Dispositif de coupure

- Matériau pour les modules à coupe: acier Cr12 après traitement

- Dureté pour traitement thermique: HRC55 - 60°

- Type de coupure: hydraulique, automatique

- Moteur pour support hydraulique: 3 kW

4. boîte de contrôle PLC

- Type: Système de commande de fréquence PLC avec écran tactile

- Marque de PLC: Delta

- Marque du codeur: Omron

- Erreur de longueur: ±2 mm

- Voltage: 380v/50HZ, trois phases

Conditions de travail

1Taille de travail: 22m x 2m x 4m

2Énergie: 6 kW

3Fréquence: 50 à 60 Hz

4Fil/câble: 4-6 mm2 (longueur selon l'atelier)

5Coût de la main-d'œuvre: 2 travailleurs

6Outils: fermeture à clef et tournevis

7Appareil de levage: chariot élévateur ou grue de 3 à 5 t

Installation et formation

1. Si les acheteurs visitent notre usine et vérifient la machine, nous vous apprendrons à installer et à utiliser la machine, et aussi à former vos travailleurs/techniciens en face à face.

2Sans visite, nous vous enverrons un manuel d'utilisation et une vidéo pour vous apprendre à installer et à utiliser.

3. Si l'acheteur a besoin de notre technicien pour aller à votre usine locale, s'il vous plaît organiser des billets aller-retour, nourriture et hôtel et salaire quotidien USD100, coût du visa et les choses nécessaires.

Notre usine

Cangzhou Best machinery manufacturing Co., Ltd. est un fabricant professionnel engagé dans la machine de formage à rouleaux froids de haute qualité.Notre ingénieur professionnel engagé dans la conception de machines de formage à froid depuis plus de 20 ans, a une richesse de concept de conception.

Nous nous sommes spécialisés dans la production de machines de formage de rouleaux de carreaux C/Z/U, de machines de formage de rouleaux de plancher, de machines de formage de rouleaux de série de portes, de machines de formage de rouleaux de plateaux de câbles,machine de formage de rouleaux de panneaux de toit/mur, machine de formage de rouleaux en acier léger, machine de formage de rouleaux en K-span, machine de formage de rouleaux de canaux d'eau, machine de formage de rouleaux de carreaux vitrés/toilettes, machine de formage de rouleaux de garde-corps pour autoroutes,ligne de production de panneaux sandwich, machine de formage de rouleaux, machine à découper, machine à plier et à couper, certains équipements auxiliaires.

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!